The visit combined connecting with a number of certified businesses in the region and a visit to the FOOMA Trade Show in Tokyo hosted by the Japan Food Machinery Manufacturers Association.

In addition to visiting a number of certified businesses on their stands, Mr Stone had the opportunity to speak with several businesses whose product had ‘food safety’ characteristics. “It was great to meet with our certified customers on their stands and to see how they are presenting their products to the marketplace”, Mr Stone commented, “they all feel that ‘food safety’ is a key differentiating point with their products and were eager to promote this aspect” . “The HACCP International certification that they carry verifies their food safety promises to the market and these customers take advantage of the recognition and prestige associated with the use of the certification mark”, he added.

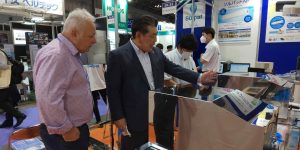

Director of HACCP International, Martin Stone, inspects hand sanitation equipment at FOOMA Tokyo with Mr Shinji Ogihara – President – Work Solution Co., Ltd, a HACCP International Certified company.

Through attending these shows over the years, Mr Stone has witnessed the elevation of food safety characteristics for non-food items to become a major selling point for those products. “The number of businesses using these characteristics as points of product differentiation has increased year on year”, Mr Stone observed. “It was very interesting to note the number of suppliers throughout the trade show claiming food safety benefit through the use of their products or services”, he added.

And for good reason. Food safety is seen as the essential quality aspect of food and food manufacturers have extended this requirement to the materials, equipment and services they use in their facilities. Advanced methodologies and standards such as HACCP and GFSI accredited standards provide excellent food safety assurance in regard to the food manufacturers operations. This leaves those materials, services and equipment used by the food business presenting a risk that requires control in regard to food safety impact.

Around 100,000 people from 20,000 food businesses visited FOOMA this year in Tokyo. And next year is expected to be an even larger event. Organisers have also grasped the importance of food safety for equipment, materials and services in their published objectives for 2024; To promote the exchange and dissemination of technology and information related to food machinery, equipment, and related devices, as well as to contribute to the further development of the food industry. With the growing interest in “food safety and security,” a “prosperous future pioneered by food technology” is proposed through cutting-edge food machinery technologies, products, and services.

Managing Director – Japan and Korea, Mr Nigel Asai, Meets customers at FOOMA including Mr Satoru Maruyama – Vice President – Hoshizaki Sales Co. Ltd and Senior Managing Director – Hoshizaki Co. Ltd, a HACCP International Certified equipment manufacturer.

Certified customers from Japan such as Saraya, Atago and Pack Style each have outstanding products exhibiting clear food safety advantages to the food business users… and ultimately to the consumers. “Meeting with these important customers provided insight into their food safety commitment to the marketplace”, says Mr Stone.

“Saraya have been a significant supplier in the cleaning and sanitation chemical space for many years and have an outstanding range of food-safe chemicals available”. “Monitoring is a fundemantal part of all HACCP based Food Safety Management systems and Atago supply some of the best designed and practical monitoring equipment available for the food industry”. “Pack Style produce a range of innovative packaging solutions for meals that not only address environmental concerns but deliver excellent food-safety assurances”, Mr Stone explains.

Mr Stone had the opportunity to meet with the Japan HACCP Training Centre. “Exchanging views with a leading expert in Japan, Director, Mr Sugiura, was most interesting and provided insight into Japanese Food Safety Culture and trends in the food manufacturing environment in regard to food safety”, says Mr Stone.

During the FOOMA Trade show, Mr Stone was interviewed for the Monthly HACCP Magazine published by the HACCP Training Centre. Among other things, he was asked about the changes he has observed in the Japanese food industry in regard to food safety over a period of some 30 years of direct experience. “Japan has always had a cultural association with the concept of safety”, he said, “and this extends through the food manufacturing industry in terms of food safety”. “What is interesting, is the continued growth of awareness from the suppliers of equipment, materials and services to the food industry and how these suppliers are promoting their achievements to the demanding food industry”.

Prior to the show attendance, Mr Stone had the opportunity to meet with the management team at The Japan Ready-made Meal Association who provided information on the growth of this sector in Japan and were most interested in food safety management developments from around the world.

Mr Stone further met with a number of HACCP International certified companies including Kitchenista, Kurarey and 3M Japan who each have excellent products in terms of applied food safety. “These companies are at the fore-front of providing quality, food-safe materials to the food industry in Japan”, said Mr Stone. These organisations are working with a leading distributor, OZAX, to further highlight and promote food safety management and the importance of using materials in the food industry that are of the highest standard in regard to food safety.

Mr Stone concludes, “As evidenced by our many certified suppliers in Japan, it is clear that these companies are at the forefront of innovation for their products where food safety is an integral part of the design of the equipment, materials and services that they provide to the food industry, both in Japan and around the world”.